- Tightness of the emulsion.

- Specific gravity of the oil and produced water.

- Corrosiveness of the crude oil, produced water, and casing head gas.

- Scaling tendencies of the produced water.

- Quantity of fluid to be treated and percent water in the fluid.

- Paraffin-forming tendencies of the crude oil.

- Desirable operating pressures for equipment.

- Availability of a sales outlet and value of the casing head gas produced.

Why Remove Water?

- Wet Oil has Little Value

– Refineries usually specify <0.5% water

- The presence of water can lead to corrosion

– In shipping lines and process equipment

– In Refinery process systems

- System Designs

– Most oil production systems are sized for oil

- Transport Costs

– Transporting a by-product with no value is wasteful

- Removing water from oil (Deoiling), although desirable, creates potential problems:

– Disposal of oily separated water

- Standards from as high as 40ppm hydrocarbon (offshore) to as low as 5ppm hydrocarbon (onshore)

- Standards often exceeded due to operational problems

– Solids build up in production systems

What is an Emulsion?

- Definition: A mixture of two immiscible liquids, one of which is dispersed as droplets in the other, this dispersion being stabilized by an emulsifying agent.

- Water in Oil Emulsions (W/O)

– “Normal” Emulsion

– Continuous phase – Oil

– Dispersed phase – Water

Oil in Water Emulsions (O/W)

– “Reverse” Emulsion

– Continuous phase – Water

– Dispersed phase – Oil

- Two Immiscible Liquids

– Oil and Water

Source of Oil and Water:

What is Required For Emulsion Formation?

- Two Immiscible Liquids

– Oil and Water

- A Source of Mixing Energy / Shear

– Well Bore, Pumps, Choke, Valves, Bends in Pipework, Flow Regime (Turbulent Flow)

What is Required For Emulsion Formation?

- Two Immiscible Liquids

– Oil and Water

- A Source of Mixing Energy / Shear

– Well Bore, Pumps, Choke, Valves, Bends in Pipework, Flow Regime (Turbulent Flow)

- An Emulsifying Agent(s)

– Solids e.g. Formation Fines, Corrosion Products, Scale

– Treatment Chemicals – Production and Drilling

– Natural Surfactants – e.g. Paraffins, Naphthenic Acid Salts

Major Factors Affecting “Normal” Emulsion Stability

- Type and Amount of Emulsifying Agent(s)

- Degree of Agitation (mixing)

- Viscosity of Continuous Phase – Stokes’ Law

- Density Differential of Produced Fluids – Stokes’ Law

- Disperse Phase Content (Water)

– as water content increases emulsion stability decreases (generally)

- Emulsion Age

– emulsion stability generally increases with time

- Temperature

– affects other variables

– emulsion stability decreases with increase in temperature

Stokes’ Law:

V = Velocity of water droplet

r = Radius of water droplet

dw = Density of water

do = Density of oil

u = Viscosity of oil

g = Constant

- Water droplet radius is a squared function in Stoke’s Law

- Therefore, water droplet settling velocity is most easily increased by increasing the radius of the droplets

- Hence, any means of coalescing the water droplets will increase settling velocity and reduce the settling time needed for water separation.

Resolving “Normal” Emulsions

- Demulsification

Defined as:-

“The resolution of crude oil emulsions and the subsequent removal of the separated water phase (dehydration)”

read more about Crude Oil Stabilization and Sweetening

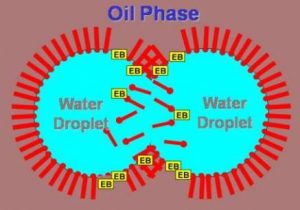

The Mechanism of Demulsifiers

- To Break (or destabilise) a “Normal” Emulsion a Demulsifier Must Achieve the Following:-

– Rapid Migration to the oil/water interface

– Flocculation

– Coalescence

– Solids Wetting

Factors In Demulsification

Solids Removal

- Removal of solids from the interface may completely resolve some emulsions

- Types of Solids:-

– Inorganic

- FeS, mineral scale (e.g. CaCO3), silt, clay, drilling muds

– Organic

- Paraffin, asphaltenes

- Solids removal can be achieved by:-

– Oil wetting (dispersion in oil)

– Water wetting (dispersion in water)

References:

1. Surface Production Operations – Ken Arnold & Maurice Stewart.

2. Production Chemistry & Corrosion Control – Baker Petrolite