in general, to the separation of any gas–liquid system such as gas–oil, gas–water, and gas–condensate systems. In almost all production operations, however, the produced fluid stream consists of three phases: oil, water, and gas.

Generally, water produced with the oil exists partly as free water and partly as water-in-oil emulsion. in both cases it should be removed or reduced to the minimum because it affects the Crude Oil Price, In some cases, however, when the water– oil ratio is very high, oil-in-water rather than water-in-oil emulsion will form. Free water produced with the oil is defined as the water that will settle and separate from the oil by gravity. To separate the emulsified water, however, heat treatment, chemical treatment, electrostatic treatment, or a combination of these treatments would be necessary in addition to gravity settling.Therefore, it is advantageous to first separate the free water from the oil to minimize the treatment costs of the emulsion treatment.

Along with the water and oil, gas will always be present and, therefore, must be separated from the liquid. The volume of gas depends largely on the producing and separation conditions. When the volume of gas is relatively small compared to the volume of liquid, the method used to separate free water, oil and gas is called a free-water knockout. In such a case, the separation of the water from oil will govern the design of the vessel. When there is a large volume of gas to be separated from the liquid (oil and water), the vessel is called a three-phase separator and either the gas capacity requirements or the water–oil separation constraints may govern the vessel design. Free-water knockout and three-phase separators are basically similar in shape and components. Further, the same design

concepts and procedures are used for both types of vessel.

read also Gas - Oil Separators

Three-phase separators may be either horizontal or vertical pressure vessels similar to the two-phase separators However, three-phase separators will have additional control devices and may have additional internal components. In the following sections, the two types of separator (horizontal and vertical) are described and the basic design equations are developed.

Horizontal Three Phase Separators

Three-phase separators differ from two-phase separators in that the liquid collection section of the three-phase separator handles two immiscible liquids (oil and water) rather than one. This section should, therefore, be

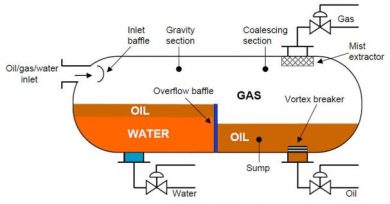

designed to separate the two liquids, provide means for controlling the level of each liquid, and provide separate outlets for each liquid. figure above show schematics of two common types of horizontal three-phase separators. The difference between the two types is mainly in the method of controlling the levels of the oil and water phases. An interface controller and a weir provide the control. The design of the second type , normally known as the bucket and weir design, eliminates the need for an interface controller.

The operation of the separator is, in general, similar to that of the two-phase separator. The produced fluid stream, coming either directly from the producing wells or from a free-water knockout vessel, enters the separator and hits the inlet diverter, where the initial bulk separation of the gas and liquid takes place due to the change in momentum and difference in fluid densities. The gas flows horizontally through the gravity settling section (the top part of the separator) where the entrained liquid droplets, down to a certain minimum size (normally 100 mm), are separated

by gravity. The gas then flows through the mist extractor, where smaller entrained liquid droplets are separated, and out of the separator through the pressure control valve, which controls the operating pressure of the

separator and maintains it at a constant value. The bulk of liquid, separated at the inlet diverter, flows downward, normally through a downcomer that directs the flow below the oil–water interface. The flow of the liquid through the water layer, called water washing, helps in the coalescence and separation of the water droplets suspended in the continuous oil phase. The liquid collection section should have sufficient volume to allow enough time for the separation of the oil and emulsion from the water. The oil and emulsion layer forming on top of the water is

called the oil pad. The weir controls the level of the oil pad and an interface controller controls the level of the water and operates the water outlet valve. The oil and emulsion flow over the weir and collect in a separate compartment, where its level is controlled by a level controller that operates the oil outlet valve.

The relative volumes occupied by the gas and liquid within the separator depend on the relative volumes of gas and liquid produced. It is a common practice, however, to assume that each of the two phases occupies 50% of the separator volume. In such cases, however, where the produced volume of one phase is much smaller or much larger than the other phase, the volume of the separator should be split accordingly between the phases. For example, if the gas–liquid ratio is relatively low, we may design the separator such that the liquid occupies 75% of the separator volume and the gas occupies the remaining 25% of the volume. The operation of the other type of horizontal separator differs only in the method of controlling the levels of the fluids. The oil and emulsion flow over the oil weir into the oil bucket, where its level is controlled by a simple level controller that operates the oil outlet valve.

read also Two-Phase Gas - Oil Separation

The water flows through the space below the oil bucket, then over the water weir into the water collection section, where its level is controlled by a level controller that operates the water outlet valve. The level of the liquid in the separator, normally at the center, is controlled by the height of the oil weir. The thickness of the oil pad must be sufficient to provide adequate oil retention time. This is controlled by the height of the water weir relative to that of the oil weir.

Vertical Three-Phase Separators

phase separation. However, in certain applications, the engineer may be forced to select a vertical separator instead of a horizontal separator despite the process-related advantages of the later. An example of such applications is found in offshore operations, where the space limitations on the production platform may necessitate the use of a vertical separator.

The produced fluid stream enters the separator from the side and hits the inlet diverter, where the bulk separation of the gas from the liquid takes place. The gas flows upward through the gravity settling sections which are designed to allow separation of liquid droplets down to a certain minimum size (normally 100 mm) from the gas. The gas then flows through the mist extractor, where the smaller liquid droplets are removed. The gas leaves the separator at the top through a pressure control valve that controls the separator pressure and maintains it at a constant value.

The liquid flows downward through a downcomer and a flow spreader that is located at the oil–water interface. As the liquid comes out of the spreader, the oil rises to the oil pad and the water droplets entrapped in the oil settle down and flow, countercurrent to the rising oil phase, to collect in the water collection section at the bottom of the

separator. The oil flows over a weir into an oil chamber and out of the separator through the oil outlet valve. A level controller controls the oil level in the chamber and operates the oil outlet valve. Similarly, the water out of the spreader flows downward into the water collection section, whereas the oil droplets entrapped in the water rise, countercurrent to the water flow, into the oil pad. An interface controller that operates the water outlet valve controls the water level.

The use of the oil weir and chamber in this design provides good separation of water from oil, as the oil has to rise to the full height of the weir before leaving the separator. The oil chamber, however, presents some problems. First, it takes up space and reduces the separator volume needed for the retention times of oil and water. It also provides a place for sediments and solids to collect, which creates cleaning problems and may hinder the flow of oil out

of the vessel. In addition, it adds to the cost of the separator.Liquid–liquid interface controllers will function effectively as long as there is an appreciable difference between the densities of the two liquids.

In most three-phase separator applications, water–oil emulsion forms and a water–emulsion interface will be present in the separator instead of a water–oil interface. The density of the emulsion is higher than that of the

oil and may be too close to that of the water. Therefore, the smaller density difference at the water–emulsion interface will adversely affect the operation of the interface controller. The presence of emulsion in the separator takes up space that otherwise would be available for the oil and/or the water. This reduces the retention time of the oil and/or water and, thus results in a less efficient oil–water separation. In most operations where the presence of emulsion is problematic, chemicals known as deemulsifying agents are injected into the fluid stream to mix with the

liquid phase. Another method that is also used for the same purpose is the addition of heat to the liquid within the separator. In both cases, however, the economics of the operations have to be weighted against the technical constraints.

Separation Theory

in general, valid for three-phase separators. In particular, the equations developed for separation of liquid

droplets from the gas phase, which determined the gas capacity constraint, are exactly the same for three-phase separators.

Treatment of the liquid phase for three-phase separators is, however, different from that used for two-phase separators. The liquid retention time constraint was the only criterion used for determining the liquid capacity of two-phase separators. For three-phase separators, however, the settling and separation of the oil droplets from water and of the water droplets from oil must be considered in addition to the retention time constraint. Further, the retention time for both water and oil, which might be different, must also be considered.

In separating oil droplets from water, or water droplets from oil, a relative motion exists between the droplet and the surrounding continuous phase. An oil droplet, being smaller in density than the water, tends to move vertically upward under the gravitational or buoyant force, that the droplet settling velocity is inversely proportional to the viscosity of the continuous phase. Oil viscosity is several magnitudes higher than the water viscosity. Therefore,

the settling velocity of water droplets in oil is much smaller than the settling velocity of oil droplets in water. The time needed for a droplet to settle out of one continuous phase and reach the interface between the two phases depends on the settling velocity and the distance traveled by the droplet. In operations where the thickness of the oil pad is larger than the thickness of the water layer, water droplets would travel a longer distance to reach the water–oil interface than that traveled by the oil droplets. This, combined with the much slower settling velocity of the water droplets, makes the time needed for separation of water from oil longer than the time needed for separation of oil from water. Even in operations with a very high water–oil ratio, which might result in having

a water layer that is thicker than the oil pad, the ratio of the thickness of the water layer to that of the oil pad would not offset the effect of viscosity. Therefore, the separation of water droplets from the continuous oil phase would always be taken as the design criterion for three-phase separators.

The minimum size of the water droplet that must be removed from the oil and the minimum size of the oil droplet that must be removed from the water to achieve a certain oil and water quality at the separator exit depend largely on the operating conditions and fluid properties. Results obtained from laboratory tests conducted under simulated field conditions provide the best data for design. The next best source of data could be obtained from nearby fields. If such data are not available, the minimum water droplet size to be removed from the oil is taken as 500 mm.

Separators design with this criterion have produced oil and emulsion containing between 5% and 10% water. Such produced oil and emulsion could be treated easily in the oil dehydration facility.

Retention Time

Another important aspect of separator design is the retention time, which determines the required liquid volumes within the separator. The oil phase needs to be retained within the separator for a period of time that is sufficient for the oil to reach equilibrium and liberates the dissolved gas.

The retention time should also be sufficient for appreciable coalescence of the water droplets suspended in the oil to promote effective settling and separation. Similarly, the water phase needs to be retained within the separator for a period of time that is sufficient for coalescence of the suspended oil droplets. The retention times for oil and water are best determined from laboratory tests; they usually range from 3 to 30 min, based on operating conditions and fluid properties. If such laboratory data are not available, it is a common practice to use a retention time of 10 min

for both oil and water.

References:

1. Oil and gas Production Handbook.

2. Oil and Gas Field Processing – King Fahd University of Petroleum and Minerals.