Inlet Diverters

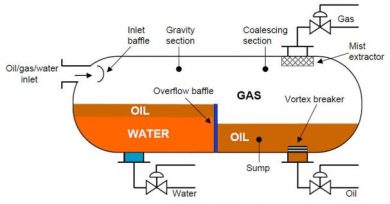

Inlet diverters are used to cause the initial bulk separation of liquid and gas. The most common type is the baffle plate diverter, which could be in the shape of a flat plate, a spherical dish, or a cone. Another type, is the

centrifugal diverter; it is more efficient but more expensive. The diverter provides a means to cause a sudden and rapid change of momentum (velocity and direction) of the entering fluid stream. This, along with the difference in densities of the liquid and gas, causes fluids separation.

Wave Breakers

In long horizontal separators, waves may develop at the gas–liquid interface. This creates unsteady fluctuations in the liquid level and would negatively affect the performance of the liquid level controller. To avoid this, wave breakers, which consist of vertical baffles installed perpendicular to the flow direction, are used.

Defoaming Plates

Depending on the type of oil and presence of impurities, foam may form at the gas–liquid interface. This results in the following serious operational problems:

1. Foam will occupy a large space in the separator that otherwise would be available for the separation process; therefore, the separator efficiency will be reduced unless the separator is oversized to allow for the presence of foam.

2. The foam, having a density between that of the liquid and gas, will disrupt the operation of the level controller.

3. If the volume of the foam grows, it will be entrained in the gas and liquid streams exiting the separator; thus, the separation process will be ineffective. The entrainment of liquid with the exiting gas is known as liquid carryover. Liquid carryover could also occur as a result of a normally high liquid level, a plugged liquid outlet, or an undersized separator with regard to liquid capacity. The entrainment of gas in the exiting liquid is known as gas blowby. This could also occur as a result of a normally low liquid level, an undersized separator with regard to gas capacity,

or formation of a vortex at the liquid outlet.

Foaming problems may be effectively alleviated by the installation of defoaming plates within the separator. Defoaming plates are basically a series of inclined closely spaced parallel plates. The flow of the foam through such plates results in the coalescence of bubbles and separation of the liquid from the gas.

In some situations, special chemicals known as foam depressants may be added to the fluid mixture to solve foaming problems. The cost of such chemicals could, however, become prohibitive when handling high production rates.

Vortex Breaker

A vortex breaker, similar in shape to those used in bathroom sink drains, is normally installed on the liquid outlet to prevent formation of a vortex when the liquid outlet valve is open. The formation of a vortex at the liquid outlet may result in withdrawal and entrainment of gas with the exiting liquid (gas blowby).

Sand Jets and Drains

As explained previously , formation sand may be produced with the fluids. Some of this sand will settle and accumulate at the bottom of the separator. This takes up separator volume and disrupts the efficiency of

separation. In such cases, vertical separators will be preferred over horizontal separators. However, when horizontal separators are needed, the separator should be equipped with sand jets and drains along the bottom of the separator. Normally, produced water is injected though the jets to fluidize the accumulated sand, which is then removed through the drains.

Design Principles and Sizing of Gas–Oil Separators

In this section, some basic assumptions and fundamentals used in sizing gas–oil separators are presented first. Next, the equations used for designing vertical and horizontal separators are derived. This will imply finding the diameter and length of a separator for given conditions of oil and gas flow rates, or vice versa.

Assumptions

1. No oil foaming takes place during the gas–oil separation (otherwise retention time has to be drastically increased as explained earlier).

2. The cloud point of the oil and the hydrate point of the gas are below the operating temperature.

3. The smallest separable liquid drops are spherical ones having a diameter of 100 mm.

4. Liquid carryover with the separated gas does not exceed 0.10 gallon/MMSCF (M¼1000).

Fundamentals

1. The difference in densities between liquid and gas is taken as a basis for sizing the gas capacity of the separator .

2. A normal liquid (oil) retention time for gas to separate from oil is between 30 s and 3 min. Under foaming conditions, more time is considered (5–20 min). Retention time is known also as the residence time (¼V/Q, where V is the volume of vessel occupied by oil and Q is the liquid flow rate).

3. In the gravity settling section, liquid drops will settle at a terminal velocity that is reached when the gravity force Fg acting on the oil drop balances the drag force (Fd) exerted by the surrounding fluid or gas.

4. For vertical separators, liquid droplets (oil) separate by settling downward against an up-flowing gas stream; for horizontal ones, liquid droplets assume a trajectory like path while it flows through the vessel (the trajectory of a bullet fired from a gun).

5. For vertical separators, the gas capacity is proportional to the cross-sectional area of the separator, whereas for

horizontal separators, gas capacity is proportional to area of disengagement (LD) (i.e., length diameter).

Settling of Oil Droplets

In separating oil droplets from the gas in the gravity settling section of a separator, a relative motion exists between the particle, which is the oil droplet, and the surrounding fluid, which is the gas. An oil droplet, being much greater in density than the gas, tends to move vertically downward under the gravitational or buoyant force, Fg.

The fluid (gas), on the other hand, exerts a drag force, Fd, on the oil droplet in the opposite direction. The oil droplet will accelerate until the frictional resistance of the fluid drag force, Fd, approaches and balances Fg; and, thereafter, the oil droplet continues to fall at a constant velocity known as the settling or terminal velocity.

read also:

Gas – Oil Separators Part.1

2-phase Gas Oil Separation

References:

1. Petroleum and Gas Field Processing – H. K. Abdel-Aal and Mohamed Eggour.

2. Oil & Gas Production Handbook.