DESCRIPTION SCHEME AND FUNCTIONING

It is one of the most important systems in any oil facility, because fuel gas is the main fuel for the whole plant, the most commonly used fuel in hydrocarbon treatment plants is natural gas because it is locally available and therefore financially more convenient than other fuels. Gas can be produced directly from the wells or obtained through the treatment of raw gas.

The users can use fuel gas, only if its pressure is appropriate for the

equipment and if it doesn’t contain liquid and solid impurities.

EQUIPMENT DESCRIPTION AND PERFORMANCE

The fuel gas feed comes from gas treatment pipelines or vessels containing saturated gas and is composed of:

– Various pressure reducers with several calibrating parameters;

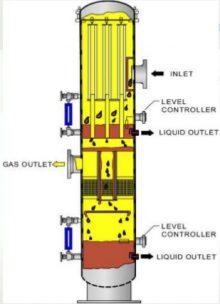

– a separator for separating any possible liquid phase carryover and/or condensed along the supply line;

– an indirect fire or electric heater to avoid the formation of liquids (water-gas oil) along the supply line during pressure reduction;

– Filters provided to remove any possible solid substances present inside the gas that could damage instruments and equipment.

The separators are usually of the scrubber type that is more efficient than normal separators because they are provided with demisters capable of withholding particles of liquid mist.

In the fuel gas treatment manifold, the reducers are located in parallel position to adequately respond to heavy demands when, downstream of the reducers, several users request fuel at the same time

Where fuel gas comes from?

– It might be a dry gas stream that is the LPG plant output, which is mainly, consists of C1, and sometimes C1+C2, free of water and liquids.

– if there is no dry gas, natural gas can be used as fuel, but after being dehydrated, and/or passed through a scrubber that eliminates liquids or condensates.

Where we use fuel gas in any crude oil or natural gas facility?

- in heaters “whether direct or indirect” as a fuel for the burners.

- as a blanketing gas for storage tanks or vessels, especially in the ones that are a suction for a pump to avoid collapse.

- as a purge gas and that is to expel any air in the pipelines.

- as an eternization for the flares, and sometimes in the pilot ignition panels used with gas flares or blowdowns.

- as a fuel for gas turbines used in gas compressor stations or anywhere else, it goes to the flame chambers or as a starting gas in starters that work with fuel gas, because some starters are driven with an electric motor.

- fuel gas can be used as stripping gas in many cases, such as sour gases removal from crude oil, or in gas dehydration units to strip sour gases from glycol.

- it can be used in gas lift wells; it is injected to raise crude oil to the surface.

- sometimes, it is used to pressurize any vessel before start-up the process.