An emulsion-treating unit or system will use one or more of the methods to aid in destabilizing, coalescence, and/or gravity separation. Each of these treating methods is discussed separately below.

Heating. Using heat to treat crude-oil emulsions has four basic benefits:

API Spec. 12L5 recommends that crude oil be heated so that its viscosity is 50 cSt for dehydration. Viscosity should be < 7 cSt for desalting.

- Heat increases the droplets’ molecular movement, which helps coalescence by causing the dispersed-phase droplets to collide more frequently. Heat might deactivate the emulsifier (e.g., dissolve paraffin crystals), or might enhance the action of treating chemicals, causing the chemical to work faster and more thoroughly to break the film around the droplets of the dispersed phase of the emulsion.

- Heat also might increase the density difference between the oil and the water, thus accelerating settling. In general, at temperatures below 180°F, adding heat will increase the density difference. Because most light oils are treated below 180°F, the effect of heat on gravity is beneficial. For heavy crudes ( < 20°API), which normally are treated above 180°F, heat might have a negative effect on the density difference. In special cases, increased heat might cause the density of water to be less than that of oil.

Heating well fluids is expensive. Adding heat can cause a significant loss of the lower-boiling point hydrocarbons (light ends). This causes “shrinkage” of the oil, or loss of volume. Because the light ends are boiled off, the remaining liquid has a lower API gravity and thus might have less value. for 33°API crude. The vapor leaving the oil phase can be vented to a vapor recovery system or compressed and sold with the gas. Either way, there probably will be a net income loss.

The gas that is liberated when crude oil is treated also might create a problem in the treating equipment if the equipment is improperly designed. In vertical emulsion treaters and gun barrels, some liberated gas could rise through the coalescing section, creating enough turbulence and disturbance to inhibit coalescence. Perhaps more importantly, the small gas bubbles are attracted to surface-active material and, hence, to the water droplets; thus, they tend to keep the water droplets from settling and might even cause them to be discharged with the oil.

Fuel is required to provide heat, and so the cost of fuel must be considered. If the oil is above inlet-fluid temperature when it is discharged from the treating unit, it can be flowed through a heat exchanger with the incoming well fluid to transfer the heat to the cooler incoming well fluid. This will minimize evaporation losses and reduce fuel cost; however, it also will increase the vapor pressure of the crude, which might be limited by contract.

If properly done, heating an emulsion can greatly benefit water separation. Using less heat and a little more chemical, agitation, and/or settling space can obtain the most economical emulsion treatment.

In some geographic areas, emulsion-heating requirements vary in accordance with daily and/ or seasonal atmospheric temperatures. Emulsions usually are more difficult to treat when the air is cooler—e.g., at night, during a rain, or in winter months. On the other hand, treatment, especially heating, might not be required in the warmer summer months. When the treating problem is seasonal, some emulsions can be resolved successfully by adding more chemical demulsifiers during winter months. The proper economic balance of heat and chemicals requires evaluation.

Crude-oil emulsions with similar viscosity ranges do not always require the same type of treating equipment or the same treating temperature. Emulsions that are produced from different wells on the same lease or from the same formation in the same field might require different treating temperatures. For this reason, treating temperatures should be tested so that the lowest practical treating temperature for each emulsion and treating unit or system can be determined by trial.

The heat input and thus the fuel required for treating depends on the temperature rise, the amount of water in the oil, and the flow rate. Because heating a given volume of water requires approximately twice the energy needed to heat the same volume of oil, it is beneficial to separate free water from the emulsion to be treated. Often this is done in a separate free-water knockout (FWKO) vessel upstream of where heat is added. Sometimes it is accomplished in a separate section of the same vessel.

Read Also Emulsion Treating Part.1

Chemical Demulsifiers.

This treatment method is popular because the chemicals are easily applied, usually are reasonable in cost, and usually minimize the amount of heat and settling time required. The chemical counteracts the emulsifying agent, allowing the dispersed droplets of the emulsion to coalesce into larger drops and settle out of the matrix. To work, demulsifiers must be injected into the emulsion; must mix intimately with the emulsion and migrate to all the protective films surrounding all the dispersed droplets; and must displace or nullify the effect of the emulsifying agent at the interface. For the oil and water to separate, there must also be a period of continual, moderate agitation of the treated emulsion to produce contact between and coalescence of the dispersed droplets, as well as a quiet settling period.

Four actions are required of a chemical demulsifier:

- Strong attraction to the oil/water interface. The demulsifier must be able to migrate rapidly through the oil phase to reach the droplet interface where it must counteract the emulsifying agent.

- Flocculation. The demulsifier must have an attraction for water droplets with a similar charge and bring them together. In this way, large clusters of water droplets gather, which under a microscope look like bunches of fish eggs.

- Coalescence. After flocculation, the emulsifier film remains continuous. If the emulsifier is weak, the flocculation force might be enough to cause coalescence; however, this usually is not true, and the demulsifier must enable coalescence by neutralizing the emulsifier and promoting rupture of the droplet interface film. In the flocculated emulsion, the film rupture causes increasing water-drop size.

- Solids wetting. Iron sulfides, clays, and drilling muds can be made water-wet, which causes them to leave the interface and be diffused into the water droplets. Paraffins and asphaltenes can be dissolved or altered by the demulsifier to make their films less viscous, or they can be made oil-wet so that they will be dispersed in the oil.

The demulsifier should be selected with all functions of the treating system in mind. If the process is a settling tank, a relatively slow-acting demulsifier can be applied with good results.

On the other hand, if the system is an electrostatic process in which some of the flocculation and coalescence is accomplished by the electric field, a quick-acting demulsifier is needed or the demulsifier might need to be added farther upstream (preferable). The time required for demulsifier action in a vertical emulsion treater normally is between that in a settling tank and that in an electrostatic treater.

As field conditions change and/or the treating process is modified, the chemical requirements might change. Seasonal changes can cause paraffin-induced emulsion problems. Well workovers might change solids content, which can alter emulsion stability. Thus, no matter how satisfactory a demulsifier is, it cannot be assumed to be satisfactory over the life of the field.

Applying heat to an emulsion after a demulsifier has been mixed with it increases the chemical’s effectiveness by reducing the emulsion viscosity and facilitating more intimate chemical/ emulsion mixing. Chemical reaction at the oil/water interface happens more rapidly at higher temperatures.

Where the demulsifier is injected into the emulsion is important. It should be injected into the emulsion and mixed so that it is evenly and intimately distributed throughout the emulsion when the emulsion is heated, coalesced, and settled in the treating system. It also should be injected in a continuous stream, with the chemical volume directly proportional to the emulsion volume.

Turbulence accelerates the diffusion of the demulsifier throughout the emulsion and increases the number and intensity of impacts between water droplets. Turbulence must persist long enough to permit the chemical to reach the interface between the oil and all the dispersed water droplets, but the intensity and duration of the turbulence must be controlled so that it will not cause further emulsification. Turbulence is the dynamic factor for emulsion formation; however, a moderate level of controlled turbulence causes the dispersed droplets to collide and coalesce. Usually, this turbulence is provided by normal flow in surface lines, manifolds, and separators and by flow through the emulsion-treating unit or system.

One way to help disperse the chemical throughout the emulsion is to mix a small volume of chemical with a diluent and then to inject and mix the diluted chemical with the emulsion.

The larger volume of the mixture can help to mix the chemical more uniformly and intimately with the emulsion.

Usually, the chemical is injected into a coupling that is welded in the side of the pipe, but when flow rates are low ( < 3 ft/sec) or when laminar flow is encountered, this is not recommended.

In such cases, an injection quill (which injects the chemical in the stream at a location that is removed from the wall), a chemical distributor, and/or a static mixer are recommended. The static mixer is a series of staggered, helically convoluted vanes that use the velocity of the fluid to accomplish mixing.

When a tank of wet oil (oil that contains more than the permissible amount of water) accumulates, the tank contents can be treated by adding a small proportion of demulsifier, agitating or circulating the tank contents, and then allowing time for the water to settle in the tank. Trailer mounted units that include a heater, circulating pump, and chemical injector are sometimes used for this method of tank treating. This batch-treatment method normally is used as an emergency measure.

Using too much treating chemical not only wastes the money spent on its purchase, handling, and injection, but also can increase the stability of the water-in-oil emulsion or of the oil in-water emulsion in the produced water and increase the stability or the volume of the interfacial emulsion and/or sludge. Using too little treating chemical can fail to break the emulsion and can allow a quick buildup of emulsion and/or sludge. It also can cause an excessive need for heat to break the emulsion and for settling time to resolve the emulsion; can reduce the capacity of the treating equipment; can cause high water content in the crude oil and, therefore, the accumulation of unsalable oil and the resultant cost of retreating the crude; and can increase the difficulty of removing oil from the produced water.

Agitation.

Agitation or turbulence is necessary to form a crude-oil emulsion. When turbulence is controlled, however, it can assist in resolving the emulsion. Agitation increases the number of collisions of dispersed particles of water and increases the probability that they will coalesce and settle from the emulsion. Be careful to prevent excessive agitation that will cause further emulsification instead of resolving the emulsion. Keeping the turbulence to moderate Reynolds numbers of 50,000 to 100,000 usually achieves good coalescing conditions.

The flow of emulsions at moderate Reynolds numbers through long pipelines has been shown to cause coalescence and to develop droplets > 1,000 μm in diameter. Using a tortuous flow path as in the serpentine-pipe flow-coalescing device can decrease the pipeline length required for coalescence. Other devices that are described below have largely supplanted this technology.

Coalescing Plates.

Properly designed and placed baffle plates can assist demulsification by evenly distributing emulsion in a vessel and causing gentle agitation that helps to coalesce the droplets by causing dispersed water particles to collide. Using too much baffling, however, can cause excessive turbulence, which might increase emulsification and impede water-droplet settling. Special perforated baffle plates that are properly placed inside treating vessels provide surfaces on which water droplets can coalesce. The emulsion flowing through the perforations creates slight agitation in the form of eddy currents, which causes coalescence. If the perforations are too small, however, shearing of the water droplets can occur, yielding a tighter emulsion. Other baffle-plate designs also provide surfaces for water coalescence. water droplets to contact the plates and coalesce with a film on the surface of the plates. This type of plate can become plugged if used in situations with high paraffin deposition.

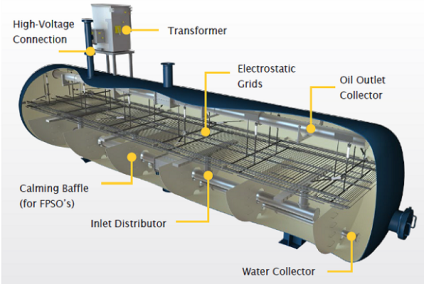

Electrostatic Coalescence.

- The water droplets become polarized and tend to align themselves with the lines of electric force. In so doing, the positive and negative poles of the droplets are brought adjacent to each other. Electrical attraction brings the droplets together and causes them to coalesce.

- An induced electric charge attracts the water droplets to an electrode. In a direct current (DC) field, the droplets tend to collect on the electrodes or bounce between the electrodes, forming larger and larger droplets until eventually they settle by gravity.

- The electric field distorts and thus weakens the film of emulsifier surrounding the water droplets. Water droplets dispersed in oil that are subjected to a sinusoidal alternating-current (AC) field become elongated along the lines of force as voltage rises during the first half-cycle.

As the droplets are relaxed during the low-voltage part of the cycle, the surface tension pulls them back toward a spherical shape. This effect repeats with each cycle, weakening the film so that it breaks more easily when droplets collide.

Whatever the actual mechanism, the electrical field causes the droplets to move about rapidly, which increases the probability of collision with other droplets. Droplets coalesce when they collide at the proper velocity. The greater the voltage gradient, the greater the forces that cause coalescence; however, experimental data have shown that at some voltage gradient, rather than coalescing, the water droplets can be pulled apart, tightening the emulsion. For this reason, electrostatic treaters normally are equipped with a mechanism for adjusting the voltage gradient in the field.

In oil that contains a large quantity of water, there is a tendency toward “chaining”—the formation of a chain of charged water particles—which might form links between the two electrodes, causing short-circuiting. Chaining has been observed in emulsions that contain 4% or less water. If chaining causes excess power consumption, the voltage gradient is too large (i.e., the electrical grids of the electrostatic treater are too close together or the voltage is too high) for the amount of water being handled. The breaking out of solution of small amounts of gas also can create sufficient turbulence to impede sedimentation.

References:

1. Petroleum Engineering Handbook – Larry W. Lake.

2. Petroleum and Gas Field Processing – H.K AbdelAll & Mohammed Aggour.

3. Surface Production Operations Vol 1 & 2 – Ken Arnold & Maurice Stewart.

Thanks, it’s very informative