Most of the world’s oil reservoirs now produce a mixture of oil and water. The liquids are subjected to shear forces through pumps or other lifting methods, or are sheared as they pass through pressure-reducing devices in the production line. The shear forces disperse one liquid into the other with variations in drop size and stability that are related to the shear force encountered and the physicochemical nature of the production stream. Such dispersions commonly are referred to as emulsions, although many are not true emulsions.

In a true emulsion, either the drop size must be small enough that forces from thermal collisions with molecules of the continuous phase produce Brownian motion that prevents settling, or the characteristics of the interfacial surfaces must be modified by surfactants, suspended solids, or another semisoluble material that renders the surface free energy low enough to preclude its acting as a driving force for coalescence.

Even in fields where there is essentially no initial water production, water cuts eventually might increase enough to make emulsion treatment necessary. Water content of the untreated oil varies from < 1 to > 90 vol%. Salt and basic-sediment-and-water (BS&W) contents are important crude-purchasing requirements. Purchasers limit these contents in the oil they purchase to reduce transportation costs, water treatment and disposal costs, and equipment corrosion.

Removing water from the stream decreases the salt content, but additional steps might be required to meet salt specifications. BS&W content limits vary according to local conditions, practices, and contractual agreements, but typically range from 0.2 to 3.0%. BS&W usually is predominantly water, but might contain solids, some of which are sand, silt, mud, scale, and precipitates of dissolved solids from the producing formation. Other sources of solids are corrosion products, bacterial debris, and precipitated petroleum fractions such as asphaltenes (read also Oilfield Parrafins and Asphaltenes). Solids are troublesome and vary widely among producing fields, zones, and wells.

When water forms a stable emulsion with crude oil and cannot be removed in conventional storage tanks, emulsion-treating methods must be used. This chapter covers the procedures and equipment that are used in treating emulsions.

Definition of an Emulsion:

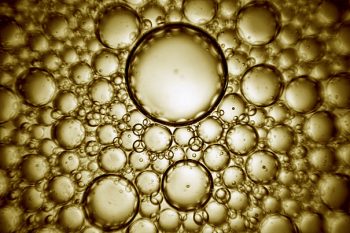

Strictly speaking, an emulsion is a heterogeneous liquid that consists of two immiscible liquids, one of which is intimately dispersed as droplets in the other.

In oilfield parlance, though, an emulsion is any liquid/liquid dispersion that does not readily separate. This latter definition is the one used in this chapter, with apologies to the purists who would call these fine dispersions, rather than emulsions.

The stability of the emulsion is controlled by the types and amounts of surface-active agent and/or finely divided solids, which commonly act as emulsifying agents, or emulsifiers. Emulsifying agents form interfacial films around the droplets of the dispersed phase and create a barrier that slows or prevents coalescence of the droplets.

The matrix of an emulsion is called the external (or continuous) phase. The portion of the emulsion that is in the form of small droplets is called the internal (or dispersed or discontinuous) phase. This chapter considers emulsions of crude oil and the water or brine that is produced with it.

In most crude-oil/water emulsions, the water is finely dispersed in the oil. Such a water-in oil emulsion is referred to as a “normal” emulsion. The oil can be dispersed in the water to form an oil-in-water emulsion, which is known as an “inverse” or “reverse” emulsion.

Emulsions sometimes are interrelated in a more complex form. The emulsion might begin as either water-in-oil or oil-in-water, but become multistage with additional agitation. If it is water-in-oil initially, a water-in-oil-in-water emulsion can be formed if a small volume of the original water-in-oil emulsion is enveloped in a film of water. Multistage emulsions usually add appreciably to the problem of separating the emulsion into oil and water. The more violent the agitation, the more likely multistage emulsions are to form.

How Crude-Oil Emulsions Form:

For an emulsion to form, the two liquids forming the emulsion must be immiscible, there must be sufficient agitation to disperse one liquid as droplets in the other, and an emulsifying agent must be present.

Most crude-oil emulsions are the water-in-oil type, although oil-in-water emulsions are encountered in some heavy-oil production (e.g., in areas of Canada; in Venezuela; and in California, U.S.A.). Oil-in-water emulsions generally are resolved in the same way as are water in-oil emulsions, except that electrostatic treaters cannot be used on them.

The agitation that is needed to form an emulsion may result from the bottomhole pump; flow through the tubing, wellhead, manifold, or flowlines; the surface transfer pump; pressure drop through chokes, valves, or other surface equipment; or any combination of these. The more agitation present, the smaller the water droplets that are dispersed in the oil. Studies of water-in-oil emulsions have shown that water droplet sizes vary widely, from < 1 to approximately 1,000 μm. Emulsions with smaller water droplets usually are more stable and difficult to treat than are those with larger droplets.

Crude oils vary considerably in emulsifying tendency. Some form very stable emulsions that are difficult to separate. Others do not emulsify or form loose emulsions that separate quickly. In an untreated emulsion, the density difference between the oil and the water will cause a certain amount of water to separate from the oil by natural coalescence and settling; however, unless some form of treatment is used to accomplish complete separation, a small percentage of water probably will remain in the oil, even after extended settling. The remaining water will be in minute droplets that have extremely low settling velocities. These droplets also will be widely dispersed, so that they have little chance to collide, coalesce into larger droplets, and settle.

The amount of water that emulsifies with crude oil in most production systems can vary widely, ranging from < 1 to > 60 vol% (in rare cases). The most common range of emulsified water in light crude oils (i.e., above 20°API) is from 5 to 20 vol%, and in crude oils that are heavier than 20°API is from 10 to 35 vol%.

read also What are Emulsions?

Emulsifying Agents:

Emulsifying agents are surface-active compounds that attach to the water-droplet surface and lower the oil/water interfacial tension. Adding energy to the mixture by agitation breaks the dispersed-phase droplets into smaller droplets. The lower the interfacial tension, the smaller the energy input that is required for emulsification (i.e., the smaller the droplets that will form with a given amount of agitation). Some emulsifiers are asphaltic. Barely soluble in oil and strongly attracted to water, they come out of solution and attach themselves to the droplets of water as these droplets are dispersed in the oil. Asphaltic emulsifiers form thick films around the water droplets and prevent droplet surfaces from contacting when they collide, thus preventing coalescence.

Oil-wet solids (e.g., sand, silt, shale particles, crystallized paraffin, iron hydroxides, zinc compounds, aluminum sulfate, calcium carbonate, iron sulfide, and similar materials that collect at the oil/water interface) can act as emulsifiers. These substances usually originate in the oil formation, but can form because of an ineffective corrosion-inhibition program.

Most crude-oil emulsions are dynamic and transitory. The interfacial energy per unit of area is fairly high in petroleum emulsions compared to that in emulsions commonly encountered in other industries; therefore, they are thermodynamically unstable in that the total free energy will decrease if the dispersed water coalesces and separates. The interfacial film introduces an energy barrier that prevents the “breaking,” or separation, process from proceeding.

An emulsion’s characteristics change continually from the time of formation to the instant of complete resolution. Accordingly, aged emulsions can exhibit very different characteristics from those that fresh samples do. This is because any given oil contains many types of adsorbable materials and because the adsorption rate of the emulsifier and its persistence at the interface can vary. The emulsion characteristics also change when the liquid is subjected to changes in temperature, pressure, and degree of agitation.

Prevention of Emulsions:

Excluding all water from the oil while the oil is produced and/ or preventing all agitation of well fluids would prevent emulsion from forming; however, because these both are impossible, or nearly so, emulsion production must be expected from many wells. Sometimes, however, poor operating practices increase emulsification.

Operating practices that involve the production of excess water because of poor cementing or reservoir management can increase emulsion-treating problems, as can a process design that subjects the oil/water mixture to excess turbulence. Unnecessary turbulence can be caused by over pumping and poor plunger and valve maintenance in rod-pumped wells, by use of more gas lift gas than is needed, and by pumping the fluid where gravity flow could be used. To minimize turbulence, some operators use progressive cavity pumps, as opposed to reciprocating, gear, or centrifugal pumps. Other operators have found that some centrifugal pumps actually can cause coalescence if they are installed in the process without a downstream throttling valve. Wherever possible, pressure drop through chokes and control valves should be minimized before oil/water separation.

Stability of Emulsions:

Generally, crude oils with low API gravity (high density) form more stable and higher-percentage-volume emulsions than do oils of high API gravity (low density). Asphaltic-based oils tend to emulsify more readily than do paraffin-based oils. High viscosity crude oil usually forms a more stable emulsion than low-viscosity oil does. Emulsions of high-viscosity crude oil usually are very stable and difficult to treat because the viscosity of the oil hinders movement of the dispersed water droplets and thus retards their coalescence. In addition, high-viscosity/high-density oils usually contain more emulsifiers than do lighter oils.

Effect of Emulsions on Fluid Viscosity:

Emulsions always are more viscous than the clean oil in the emulsion. In oilfield emulsions, the ratio of the viscosity of an emulsion to that of the clean crude oil depends on the shear rate to which the emulsion has been subjected. For many emulsions and for the shear rates normally encountered in piping systems.

Sampling and Analyzing Crude-Oil Emulsions:

Crude-oil purchasers have established specifications that limit the amount of BS&W in the oil. These limits usually are strictly applied; if the amount of BS&W in an oil exceeds the specified limit, a purchaser might not accept the oil from the producer. The seller and buyer must agree on the procedure for sampling and analyzing the oil to provide consistent and mutually acceptable data.

Emulsion-treating unit or system performance can be monitored by periodically and regularly withdrawing and analyzing samples of the contents at multiple levels in the vessel or multiple points in the system. This is particularly beneficial when treating emulsions that involve viscous oils. Emulsion samples should be representative of the liquid from which they are taken, so emulsification should not be allowed to occur when the sample is extracted. For example, for samples obtained at the wellhead, manifold, or oil-and-gas separator, emulsification can occur because of the turbulence created while the sample is removed from the pressure zone to the sample container. Although such a sample might show a high percentage of emulsion, the oil and water in the system actually might not be emulsified.

Samples from a pressure zone can be taken without further emulsification of the liquids if the velocity of the discharging liquid is controlled. One method is to use a piece of small-diameter tubing that is 10 to 15 ft long. One end of the tubing is connected to a bleeder valve on the line or vessel from which the sample is to be extracted, and the other end is connected to the sample container. The bleeder valve is opened fully, and the sample is allowed to flow through the small-diameter tubing into the container. Emulsification caused by pressure differential may be largely eliminated by flow through small-diameter tubing; however, contact with the tubing walls might produce coalescence, or perturbations to the flow caused by the passage of solids or large water drops might produce emulsification.

Another method for withdrawing representative emulsion samples is to use a sample container that initially is filled with water and is equipped with valves at the top and bottom, with the top valve connected to the point from which the sample is to be extracted. The top valve of the container is opened first, and the container is pressured from the line. The valve at the bottom of the container then is opened, and the water is discharged into the atmosphere as the sample enters the container. No emulsification will occur in the container because there is no pressure drop between the source and sample container to cause turbulence. After the sample has been taken, pressure can be bled off through a third valve with little effect on the sample.

The BS&W content of crude oil is determined using small centrifuges that are driven by hand or by electric motor. A small measured volume of sample is diluted with solvent and placed in graduated glass containers that then are inserted into the centrifuge and spun for a few minutes at speeds of 2,000 to 4,000 rev/min. The oil, water, and solids are separated by centrifugal force, and the percentages of each can be read directly from the graduated containers in which the sample is centrifuged.

Separating a crude-oil/water emulsion into its bulk phases of oil and water usually involves three basic steps: destabilization (coagulation), coalescence (flocculation), and gravity separation (sedimentation). Operation and design parameters such as proper chemical selection, chemical-injection rate, treating temperature and pressure, continuous-phase viscosity, flow rate, vessel size and design, and fluid levels can affect separation and can be adjusted to optimize the separation process.

Step 1: Destabilization (Coagulation):

Counteracting the stabilizing effect of the emulsifier destabilizes an emulsion. To increase the probability of coalescence of dispersed water droplets on contact, the tough skin or film surrounding the dispersed water droplets must be weakened and broken. This usually is accomplished by adding heat and/or a properly selected, interfacially active chemical compound to the emulsion. (This primarily is the task of the chemical treatment program.)

Step 2: Coalescence (Flocculation):

After the films that encase the dispersed droplets have been broken or sufficiently weakened, the droplets must coalesce into drops that are large enough to settle out of the continuous phase of oil. The rate of contact of dispersed water droplets needs to be high, but without creating high shear forces. This usually is accomplished by mechanically inducing collisions between drops or by subjecting the destabilized emulsion to an electrostatic field.

Step 3: Gravity Separation (Sedimentation):

Next, there must be a quiet period of settling to allow the coalesced drops to settle out of the oil by gravity. This requires a sufficient residence time and a favorable flow pattern in a tank or vessel that will allow the coalesced drops of water to separate from the oil.

Read Also Emulsion Treatment Part.2

References:

1. Petroleum Engineering Handbook – Larry W. Lake.

2. Petroleum and Gas Field Processing – H.K AbdelAll & Mohammed Aggour.

3. Surface Production Operations Vol 1 & 2 – Ken Arnold & Maurice Stewart.

I enjoy the article

Long but worth giving time