by Abass Radhi Abbas

1.General

Communication between the formation and the wellbore will directly affect the productivity of the well. Factors such as hydrocarbon saturation, porosity, permeability, fluid properties and geometry can be measured or inferred from the measurements but they cannot usually be controlled. By contrast, completion can be controlled and thus affect well performance. During the drilling, logging and testing phase of the well, valuable information will have been gained and the relevant completion technique chosen. There are two main categories of completions to consider with, of course, many variations;

– Open hole Completions.

– Cased Hole Completions.

1.1.Openhole Completions

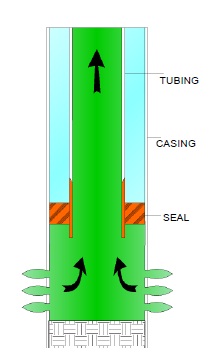

An open hole completion is when the well is drilled to the top of the target formation and the casing is cemented at this stage. Drilling is continued across the target formation and then the well is completed and produced. Open hole completions are only possible in “competent” rocks that will hold their form and not cave in or crumble – so called

– No possibility for selectively producing or treating different zones.

– Limited control of water or gas encroachment.

These two factors alone can play a significant part in the future management of the well, and this coupled with safety issues has lead the industry down the road of cased hole and perforated completions.

1.2.Cased Hole Completions

- Completion Types

Completions can be broken down into two main categories;

– Natural (perforated).

– Stimulated.

In all three the objective is to maximize production through enhancement of some aspect of the near-wellbore reservoir performance. Of particular importance is the change in flow geometry near the wellbore caused by wellbore damage (from drilling and filtrate invasion), perforations (debris), flow convergence due to partial penetration and deviation. This damage is known as skin (S) and will be discussed in more detail in section 5, but for the time being can be considered as an induced pressure drop across the completion which effects productivity.

The aim of the completion design engineer and reservoir engineer is to reduce the influence of skin as much as possible.

- 1.Natural Completions (perforated)

The natural completion is usually chosen for sandstone reservoirs with permeabilities above 10 md and porosities above 9 p.u. These reservoirs typically have small damaged zones and limited skin, good transmissibility and stable rock mechanics. They generally do not require stimulation or sand control during primary completion. The objectives of the perforation in this case would be depth of penetration and effective shot density, the perforation diameter is generally unimportant if it is larger than 0.25” (0.5 cm). The deepest penetration with the greatest phase distribution is desirable for production enhancement.

2..2 Stimulated Completions

These fall into two broad categories;

– Hydraulic Fracturing.

– Acidizing.

Occasionally the two are combined in an “acid frac” job.

2.2.1 Hydraulic Fracturing

Hydraulic fracturing is performed to enhance the effective wellbore radius rw and is usually employed in reservoirs

with small permeabilities (k < 1 md). This is accomplished by injecting fluids and propant at high pressure, in order to create a bi-wing, symmetrical fracture or crack in the reservoir. Hydraulic fracturing is generally a five-step process;

- Pre-fracturing treatment.

- Fracture initiation and breakdown.

- Fracture extension.

- Proppant injection.

- Cleanout and production.

Hydraulic Fracturing Process - 2.2.2 Acidizing

Acidizing is a stimulation process used to repair formation damage caused by the drilling or perforating operation. This type of damage is usually associated with plugging of the pore throats around the wellbore. Acidizing removes this damage from the matrix rock by injecting acid into the naturally porous rock at sub-fracturing rates, allowing the acid to dissolve the plugs. - Acid frac jobs are used to etch the surface of the hydraulically induced fracture. After the fracture closes, the etched surface cannot form a closed seal. Acid frac jobs are operationally less complicated because no proppant is used thus eliminating the potential for premature frac termination that may be caused by screenout or problems of proppant flowback. The principle disadvantage of this technique is the expense of the acid fluids and non-uniform leak-off resulting in “wormholes.” Acid frac jobs are usually performed on carbonate reservoirs

I enjoy the article

Thanks for the excellent manual