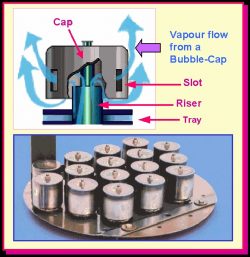

Distillation towers are the heart of a process plant, and the working component of a distillation column is the tray. A tray consists of the following components, as shown in figure below:

- Overflow, or outlet weir

- Downcomer

- Tray deck

There are two types of tray decks: perforated trays and bubble cap trays. In this chapter, we describe only perforated trays, examples of which are

- V grid, or extruded-valve caps

- Sieve decks

- Jet trays

Possibly 90 percent of the trays seen in the plant are of these types. Perforated tray decks all have one feature in common; they depend on the flow of vapor through the tray deck perforations, to prevent liquid from leaking through the tray deck. As we will see later, if liquid bypasses the outlet weir and leaks through the tray deck onto the tray below, tray separation efficiency will suffer.

Tray Efficiency

Calculate their average efficiency (the answer is 10 percent). As the vapor temperature rising from the top tray equals the liquid temperature draining from the bottom tray, the 10 trays are behaving as a single perfect tray with 100-percent efficiency. But as there are 10 trays, each tray, on average, acts like one-tenth of a perfect tray.

Poor tray efficiency is caused by one of two factors:

- Flooding

- Dumping

Downcomer Backup

Liquid flows across a tray deck toward the outlet weir. The liquid overflows the weir,

Vapor bubbles up through the sieve holes, or valve caps, on the tray deck, where the vapor comes into intimate contact with the liquid.

More precisely, the fluid on the tray is a froth or foam—that is, a mixture of vapor and liquid. In this sense, the function of a tray is to mix the vapor and liquid together to form a foam. This foam should separate back into a vapor and a liquid in the downcomer. If the foam cannot drain quickly from a downcomer onto the tray below, then the foamy liquid or froth will back up onto the tray above. This is called flooding.

Downcomer Clearance

As shown in the figure above the downcomer B is flooding. The cause is loss of the downcomer seal. The height of the outlet weir is below the bottom edge of the downcomer from the tray above. This permits vapor to flow up downcomer B. The up-flowing vapor displaces the downflowing liquid. That is, the vapor pushes the liquid up onto the tray above—which is a cause of flooding. On the other hand,

if the bottom edge of the downcomer is too close to the tray below. The high pressure drop needed for the liquid to escape from downcomer B onto tray deck 1 causes the liquid level in downcomer B to back up onto tray deck 2. Tray 2 then floods. Once tray 2 floods, downcomer C will also back up and flood.

This process will continue until all the tray decks and downcomers above downcomer B are flooded.

On the other hand, all trays in a tower below downcomer B will lose liquid levels and dry out when flooding starts in downcomer B. Thus, the following rules apply:

- When flooding starts on a tray, all the trays above that point will also flood, but trays below that point will go dry.

- An early indication of flooding in a distillation column is loss of liquid level in the bottom of the column.

- If the downcomer clearance—which means the distance between the bottom edge of the downcomer and the tray below—is too great, the downcomer becomes unsealed. Vapor flows up the downcomer, and the trays above flood.

- If the downcomer clearance is too small, then liquid backs up in the downcomer, and the trays above flood. To calculate the height of liquid in the downcomer, due to liquid flowing through the downcomer clearance:

DH = 0.6 × V2

where DH = inches of clear liquid backup in the downcomer, due to head loss under the downcomer

V = horizontal component of liquid velocity, in ft/s, as the liquid escapes from the downcomer

To guarantee a proper downcomer seal, the bottom edge of a downcomer should be about 0.5 inch below the top edge of the outlet weir. This dimension should be carefully checked by process personnel when a tower is opened for inspection. It is quite easy for sloppy tray installation to distort this critical factor.

Height of Liquid on Tray Deck

As the liquid level on a tray increases, the height of liquid in the downcomer feeding this tray will increase by the same amount.

Again, excessive downcomer liquid or froth levels result in flooding and loss of tray efficiency.

The liquid level on a tray is a function of two factors:

- Weir height

- Crest height

The weir height on many trays is adjustable. We usually adjust the weir height to between 2 and 3 inches. This produces a reasonable depth of liquid on the tray to promote good vapor-liquid contact.

The crest height is similar to the height of water overflowing a dam. It is calculated from

Crest height = 0.4 (GPM ÷ inch (outlet) weir length)0.67

where crest height = inches of clear liquid overflowing the weir

GPM = gallons (U.S.) per minute of liquid leaving the tray

The sum of the crest height plus the weir height equals the depth of liquid on the tray deck. One might now ask, “Is not the liquid level on the inlet side of the tray higher than the liquid level near the outlet weir?” While the answer is “Yes, water does flow downhill,” we design the tray to make this factor small enough to neglect.

Vapor-Flow Pressure Drop

We have yet to discuss the most important factor in determining the height of liquid in the downcomer. This is the pressure drop of the vapor flowing through the tray deck. Typically, 50 percent of the level in the downcomer is due to the flow of vapor through the trays.

When vapor flows through a tray deck, the vapor velocity increases as the vapor flows through the small openings provided by the valve caps, or sieve holes. The energy to increase the vapor velocity comes from the pressure of the flowing vapor. A common example of this is the pressure drop we measure across an orifice plate. If we have a pipeline velocity of 2 ft/s and an orifice plate hole velocity of 40 ft/s, then the energy needed to accelerate the vapor as it flows through the orifice plate comes from the pressure drop of the vapor itself.

Let us assume that vapor flowing through a tray deck undergoes a pressure drop of 1 psi (lb/in2). the pressure below tray deck 2 is 10 psig and the pressure above tray deck 2 is

9 psig. How can the liquid in downcomer B flow from an area of low pressure (9 psig) to an area of high pressure (10 psig)? The answer is gravity, or liquid head pressure.

The height of water needed to exert a liquid head pressure of 1 psi is equal to 28 inches. of water. If we were working with gasoline, which has a specific gravity of 0.70, then the height of gasoline needed to exert a liquid head pressure of 1 psi would be 28 inches/0.70 = 40 inches of clear liquid.

Total Height of Liquid in the Downcomer

To summarize, the total height of clear liquid in the downcomer is the sum of four factors:

- Liquid escape velocity from the downcomer onto the tray below.

- Weir height.

- Crest height of liquid overflowing the outlet weir.

- The pressure drop of the vapor flowing through the tray above the downcomer.

Unfortunately, we do not have clear liquid, either in the downcomer, on the tray itself, or overflowing the weir. We actually have a froth or foam called aerated liquid. While the effect of this aeration on the specific gravity of the liquid is largely unknown and is a function of many complex factors (surface tension, dirt, tray design, etc.), an aeration factor of 50 percent is often used for many hydrocarbon services.

This means that if we calculated a clear liquid level of 12 inches in our downcomer, then we would actually have a foam level in the downcomer of 12 inches/0.50 = 24 inches of foam.

If the height of the downcomer plus the height of the weir were 24 inches, then a downcomer foam height of 24 inches would correspond to downcomer flooding. This is sometimes called liquid flood.

This discussion assumes that the cross-sectional area of the downcomer is adequate for reasonable vapor-liquid separation. If the downcomer loading (GPM/ft2 of downcomer top area) is less than 150, this assumption is okay, at least for most clean services. For dirty, foamy services a downcomer loading of 100 GPM/ft2 would be safer.

Jet Flood

Figure below is a realistic picture of what we would see if our towers were made of glass. In addition to the downcomers and tray decks containing froth or foam, there is a quantity of spray, or entrained liquid, lifted above the froth level on the tray deck. The force that generates this entrainment is the flow of vapor through the tower.

The spray height of this entrained liquid is a function of two factors:

- The foam height on the tray

- The vapor velocity through the tray

High vapor velocities, combined with high foam levels, will cause the spray height to hit the underside of the tray above. This causes mixing of the liquid from a lower tray with the liquid on the upper tray. This backmixing of liquid reduces the separation, or tray efficiency, of a distillation tower.

When the vapor flow through a tray increases, the height of froth in the downcomer draining the tray will also increase. This does not affect the foam height on the tray deck until the downcomer fills with foam. Then a further increase in vapor flow causes a noticeable increase in the foam height of the tray deck, which then increases the spray height.

When the spray height from the tray below hits the tray above, this is called the incipient flood point, or the initiation of jet flooding.

Note, though, that jet flood may be caused by excessive downcomer backup. It is simple to see in a glass column separating colored water from clear methanol how tray separation efficiency is reduced as soon as the spray height equals the tray spacing.

References:

1. a Working Guide to Process Equipment – Norman P. Lieberman & Elizabeth T. Lieberman.

2. Refinery Engineering.